POLTEC Technical Data

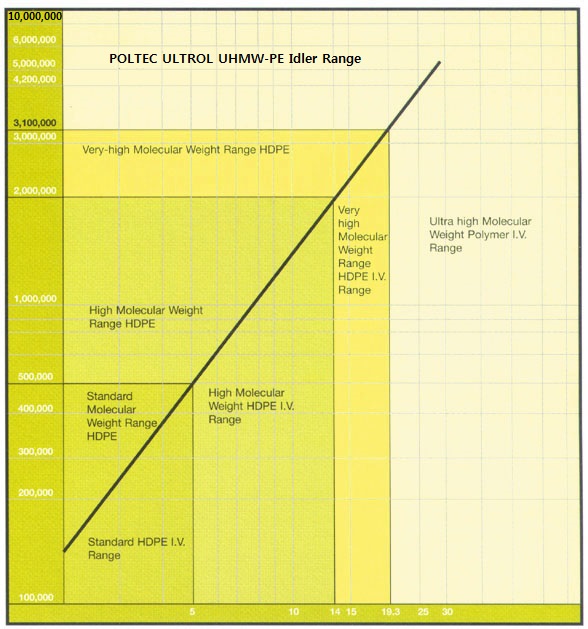

1. 1. POLTEC UHMW-PE Polymer relationship - Intrinsic Viscosity to Molecular Weight

This chart shows the various molecular weights available in polyethylene. Enhanced performance characteristics are directly related to molecular weight. When comparing the abrasion resistance, the higher the molecular weight, the greater the wear life. POTEC UHMW-PE offers exceptional wear resistant properties.

POLTEC is made from the highest molecular weight polyethylene that is consistently available.

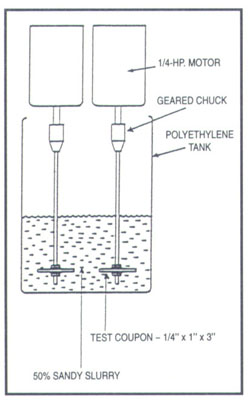

2. 2. Relative Abrasion Resistance - Sand Slurry Test

The abrasion resistance of is POL-TEC clearly demonstrated by measuring its loss of volume against other materials. Test samples are spun for a total of 7.5 hours at 1,750 rpm in a water(50%) and sand(50%) mixture

POLTECUHMW-PE attained an abrasion index rating of 10; results for the other materials tested are shown in relation to POL-TEC. Even though POL-TEC UHMW-PE is exceptionally tough, it is gentle with other materials it works with. UHMW-PE can significantly increase the wear life of contacted moving surfaces. It outwears steel 3 to 1 in sliding wear application.

Material

Abrasion Index

POLTEC UHMW-PE

Nylon 6/6

Polyurethane (D-70)

TFE

HD-PE

Stainless Steel

Polycarbonate

Carbon Steel

Polyacetal

Phosphor Bronze

Phenolic Laminate L.E.

Yellow Brass

Hard Neoprene Rubber

Hickory Wood10

24

27

72

80

84

96

100

110

120

190

400

800

9503. Relative Coefficient of Sliding Friction

This chart compares various materials to UHMW-PE. The lubricating qualities of UHMW-PE eliminate the need for lubrication, significantly reducing downtime and costly maintenance. Its low coefficient of friction allows equipment to operate smoother and quieter. It makes an excellent bearing material reducing friction and drag as well as the amount of wear, noise and abrasion associated with steel parts. UHMW-PE is an local material for dock facing and marine fender.

| Materials Used

|

Relative Coefficient

of Sliding Friction |

| Steel to steel UHMW-PE to Rolled Steel UHMW-PE to Stainless Steel UHMW-PE to UHMW-PE Urethane to Steel Nylon to Steel Teflon to Steel Acetal to Steel |

0.30 - 0.40 0.14 0.13 0.11 0.70 0.20 0.11 0.20 |

4. Physical Properties

This chart shows the physical properties of UHMW-PE. It should be noted that POLTEC UHMW-PE has the highest impact resistance of all thermal plastics. UHMW-PE has an outstanding low temperature impact strength plus high impact energy absorption. As an example of toughness, POLTEC UHMW-PE is used in gears and hammers.

Property

Units

ASTM Procedure

Results

Density at 23℃

Hardness, Rockwell "R"

Ultimate Tensile Strength at 2"/min.

Tensile Yield Strength at 2"/min.

Tensile Yield Elongation at 2"/min.

Elongation at Break at 2"/min.

1% Secant Modulus

Izod Impact at 23℃

Izod Impact at - 40℃

Durometer "D" Hardness

Deflection Temp. at 66 psi

Deflection Temp. at 264 psi

Vicat Softening Point

Coefficient of Linear Thermal Expansion

g/cc

R

psi

psi

%

%

psi

f.p.i.n.

f.p.i.n.

D/15sec

℃

℃

℃D 792

D 785

D 638

D 638

D 638

D 638

D 790B

D 256A

D 256A

D 2240

D 648

D 648

D 1525B

D 696

0.941

64

6400

3400

14

350

175,000

Non-Break

Non-Break

67

80

47

136

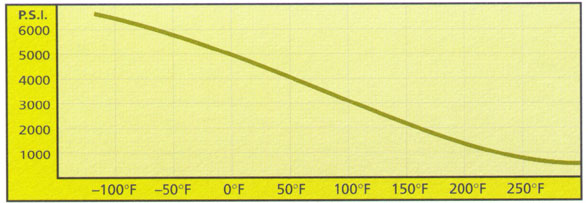

9.1×10-55. Tensile Yield Strength

This chart illustrates the psi of POL-TEC at various temperatures. At 72oF, UHMW-PE exhibits exceptional tensile strength on which a weight basis is better than that of steel.

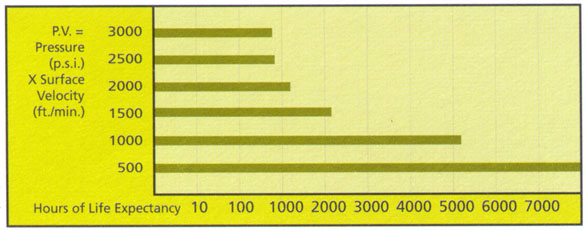

6. Compression Deformation

This chart illustrates the compression strength of POLTEC UHMW-PE for engineering purposes.

7 .UHMW-PE Chemical and Corrosion Resistance

This chart illustrates the chemical resistance of POLTEC UHMW-PE. Strong oxidizing agents and most aggressive chemicals have virtually no effect. UHMW-PE does not absorb moisture, bacteria, fungus growth and ice will not adhere to its surface, POL-TEC is an ideal material for parts operating in a chemical and corrosive environment such as sewage treatment and chemical processing plants.

|

Inorganic |

At 22.2 ℃ |

At 60 ℃ |

|||||

|

Chemical |

Time(days) |

Weight ch- ange (%) |

Appearance |

Time(days) |

Weight ch-ange (%) |

Appearance |

|

|

Chromic Acid (1N) |

30 |

+ 0.34 |

Slight Yellow |

10 |

- 0.15 |

Slight yellow |

|

|

Hydrochloric Acid,37% |

30 |

+ 0.24 |

Light Tan |

10 |

+ 0.40 |

Tan |

|

|

Hydrogen Peroxide, 30% |

30 |

- 0.01 |

No change |

10 |

+ 0.04 |

No change |

|

|

Nitric Acid, 50% |

30 |

+ 0.78 |

Brittle, attacked |

10 |

+ 4.44 |

Brittle, attacked |

|

|

Phosphoric Acid, 85% |

30 |

+ 0.07 |

No change |

10 |

+ 0.03 |

No change |

|

|

Sodium Hydroxide, 30% |

5 |

- 0.50 |

No change |

- |

- |

- |

|

|

Sodium Hypochlorite |

30 |

+ 0.04 |

No change |

10 |

+ 0.21 |

No change |

|

|

Sulfuric Acid, Fuming |

- |

- |

Decomposed in 1 Day |

- |

- |

- |

|

|

100% |

30 |

+ 0.26 |

Slight change |

10 |

+ 1.00 |

Black, attacked |

|

|

50% |

30 |

- 0.06 |

No change |

10 |

- 1.14 |

Slight change |

|

|

Water, Synthetic Sea |

30 |

+ 0.13 |

No change |

10 |

+ 0.22 |

No change |

|

|

Organic |

Acetic Acid |

30 |

+ 0.87 |

Slight Brown |

8 |

+ 0.83 |

Slight brown |

|

Acetone |

30 |

+ 0.24 |

No change |

4 |

+ 0.45 |

No change |

|

|

Benzene |

30 |

+ 6.30 |

Slight change |

4 |

+ 8.11 |

Slight change |

|

|

Carbon Tetrachloride |

30 |

+ 18.8 |

Swelled, attacked |

4 |

+ 22.4 |

Swelled, attacked |

|

|

Ethanol |

30 |

+ 0.03 |

No change |

4 |

- 0.01 |

Slight change |

|

|

Ethyl Acetate |

30 |

+ 1.34 |

Slight change |

4 |

+ 1.86 |

Slight change |

|

|

Ethyl Ether |

30 |

+ 3.9 |

Slight change |

- |

- |

- |

|

|

Ethylene Dichloride |

30 |

+ 12.2 |

Swelled, attacked |

- |

- |

- |

|

|

Gasoline |

30 |

+ 4.81 |

Slight change |

4 |

+ 6.61 |

Slight change |

|

|

Oil, Licensed |

30 |

- 0.70 |

No change |

8 |

- 0.23 |

No change |

|

|

Olive |

30 |

- 0.50 |

No change |

8 |

- 0.12 |

No change |

|

|

Transformer |

30 |

+ 2.4 |

Slight change |

8 |

+ 6.35 |

Slight swelling |

|

|

Toluene |

30 |

+ 7.0 |

Slight swelling |

8 |

+ 10.9 |

Slight swelling |

|

|

Trichlorethylene |

30 |

+ 15.0 |

Swelling, brown |

8 |

+ 26.3 |

Swelled |

|

|

Xylene |

30 |

+ 7.1 |

Slight swelling |

8 |

+ 15.5 |

Swelled |

|