POLTEC Technical Data

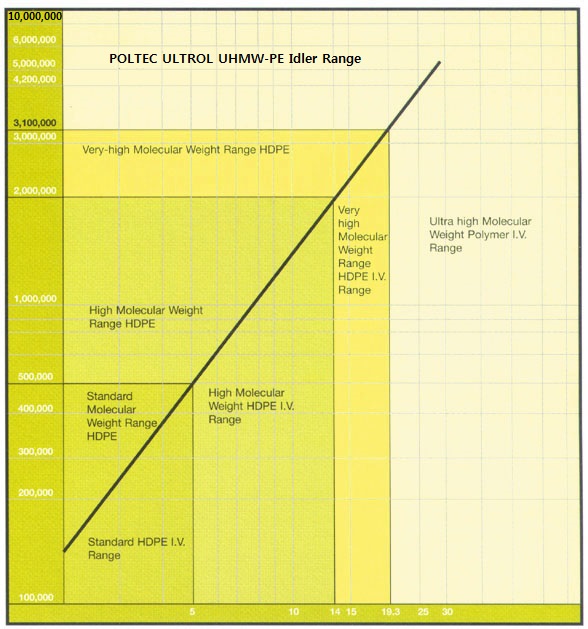

1. POLTEC UHMW Polymer Relationship - Intrinsic Viscosity to Molecular Weight (POLTEC UHMW-PE의 점도와 분자량의 관계)

이 표는 다양한 폴리에틸렌의 분자량을 보여주고 있습니다. 개선된 성능 특성들은 분자량과 직접 연관이 있습니다. 마찰 저항을 비교할 때, 분자량이 클수록 마모 수명은 더 길어집니다.

POLTEC UHMW-PE는 우수한 내마모 저항 특징을 가지고 있습니다.

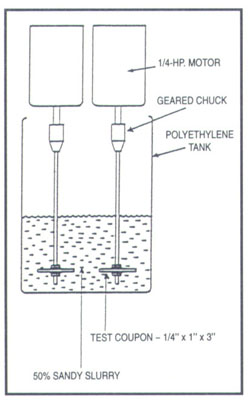

2. Relative Abrasion Resistance (상대적 마찰 저항) - Sand Slurry Test 결과

POLTEC의 마모 저항은 다른 물질에 대한 부피의 손실을 측정 함으로서 쉽게 검증 할 수 있습니다. 시험 편을 물(50%)과 모래(50%)를 혼합하여 교반속도 1,750 rpm으로 약 7.5시간 정도를 회전 시킵니다. POLTEC UHMW-PE 시편은 약 10 정도의 마모 계수를 갖으며 실험된 다른 재료의 마모량 결과치는 표와 같습니다.

Material

Abrasion Index

POLTEC UHMW-PE

Nylon 6/6

Polyurethane (D-70)

TFE

HD-PE

Stainless Steel

Polycarbonate

Carbon Steel

Polyacetal

Phosphor Bronze

Phenolic Laminate L.E.

Yellow Brass

Hard Neoprene Rubber

Hickory Wood

10

24

27

72

80

84

96

100

110

120

190

400

800

9503. Relative Coefficient of Sliding Friction (미끄럼 마찰의 상관계수)

이 표는 여러 가지 재료를 POLTEC UHMW-PE에 대하여 비교하여 본 것입니다. UHMW-PE의 자체 윤활 성질 때문에 윤활제 요구를 제거하였으며, 설비의 정지 시간과 유지 보수 비용을 확실히 줄일 수 있게 되었습니다. UHMW-PE의 낮은 마찰 계수는 설비를 보다 원활하고 정숙한 운전을 할 수 있도록 하였습니다. 이러한 성질 때문에 마찰과 끌림을 줄인 훌륭한 베어링 소재가 될 수 있을 뿐만 아니라 강 부품으로 만들어 진 부품과 연관이 있는 마모, 잡음, 마찰을 줄일 수 있게 되었습니다. UHMW-PE은 도크와 항만의 방호재료로서 사용 될 수 있습니다.

| 사용한 재료 |

미끄럼 마찰 상관계수 |

| Steel to steel POL-TEC to Rolled Steel POL-TEC to Stainless Steel POL-TEC to POL-TEC Urethane to Steel Nylon to Steel Teflon to Steel Acetal to Steel |

0.30 - 0.40 0.14 0.13 0.11 0.70 0.20 0.11 0.20 |

4. Physical Properties (물리적 성질)

이 표는 POL-TEC의 물리적 성질을 나타낸 것입니다. POLTEC UHMW-PE는 모든 열 가소성 플라스틱 중 가장 높은 내충격성과 내마모성질을 가지고 있습니다.

Property

Units

ASTM Procedure

Results

Density at 23℃

Hardness, Rockwell "R"

Ultimate Tensile Strength at 2"/min.

Tensile Yield Strength at 2"/min.

Tensile Yield Elongation at 2"/min.

Elongation at Break at 2"/min.

1% Secant Modulus

Izod Impact at 23℃

Izod Impact at - 40℃

Durometer "D" Hardness

Deflection Temp. at 66 psi

Deflection Temp. at 264 psi

Vicat Softening Point

Coefficient of Linear Thermal Expansion

g/cc

R

psi

psi

%

%

psi

f.p.i.n.

f.p.i.n.

D/15sec

℃

℃

℃D 792

D 785

D 638

D 638

D 638

D 638

D 790B

D 256A

D 256A

D 2240

D 648

D 648

D 1525B

D 696

0.941

64

6400

3400

14

350

175,000

Non-Break

Non-Break

67

80

47

136

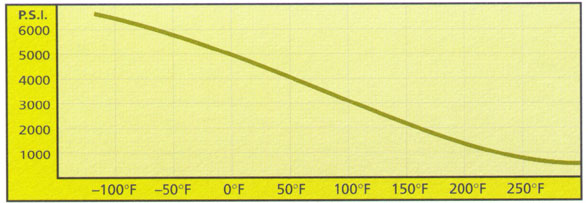

9.1×10-55. Tensile Yield Strength (인장강도)

이 표는 여러 온도에서의 인장 강도를 나타낸 것입니다.

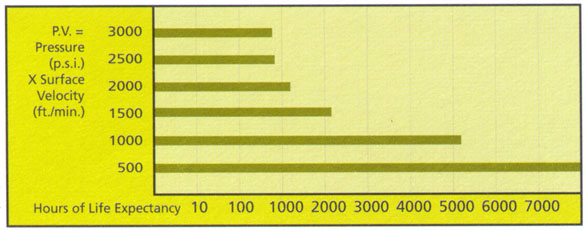

6. 베어링의 속도와 하중 인내 한계

이 표는 POLTEC UHMW-PE의 우수한 내하중 성질을 나타낸 것입니다.

7. Compression Deformation (압축 변형)

이 표는 공업용 사용을 목적한 POLTEC UHMW-PE의 압축 강도를 나타낸 것입니다.

Compressive Stress psi Compressive Value 1 min. after Removal of stress Permanent deforma- tion 24 hours after removal of stress 20℃ 282

570

850

1140

1420

17000.9

1.8

2.7

3.6

4.5

5.40.6

1.2

1.8

2.4

2.9

3.550℃ 282

570

850

1140

1420

17001.3

2.7

4.1

5.5

6.9

8.20.8

1.5

2.3

3.1

3.9

4.780℃ 282

570

850

1140

1420

17001.6

3.2

4.8

6.4

8.1

9.71.1

2.3

3.5

4.6

5.8

6.98 .POLTEC Chemical and Corrosion Resistance (POLTEC 내약품성 및 내부식성)

이 표는 POLTEC UHMW-PE의 내약품성을 나타내고 있습니다. 강력한 산화재와 대부분의 강력한 화학 물질들은 실제적으로 아무런 영향을 주지 않고 있음을 보여주고 있습니다. UHMW-PE은 수분을 흡수하지 않으며, 박테리아, 곰팡이 그리고 얼음 등이 표면에 붙지 않습니다. 그러므로, UHMW-PE은 폐수 처리와 화학 공정 등의 사용에 가장 이상적인 소재입니다.

|

Inorganic |

At 22.2 ℃ |

At 60 ℃ |

|||||

|

Chemical |

Time(days) |

Weight ch- ange (%) |

Appearance |

Time(days) |

Weight ch-ange (%) |

Appearance |

|

|

Chromic Acid (1N) |

30 |

+ 0.34 |

Slight Yellow |

10 |

- 0.15 |

Slight yellow |

|

|

Hydrochloric Acid,37% |

30 |

+ 0.24 |

Light Tan |

10 |

+ 0.40 |

Tan |

|

|

Hydrogen Peroxide, 30% |

30 |

- 0.01 |

No change |

10 |

+ 0.04 |

No change |

|

|

Nitric Acid, 50% |

30 |

+ 0.78 |

Brittle, attacked |

10 |

+ 4.44 |

Brittle, attacked |

|

|

Phosphoric Acid, 85% |

30 |

+ 0.07 |

No change |

10 |

+ 0.03 |

No change |

|

|

Sodium Hydroxide, 30% |

5 |

- 0.50 |

No change |

- |

- |

- |

|

|

Sodium Hypochlorite |

30 |

+ 0.04 |

No change |

10 |

+ 0.21 |

No change |

|

|

Sulfuric Acid, Fuming |

- |

- |

Decomposed in 1 Day |

- |

- |

- |

|

|

100% |

30 |

+ 0.26 |

Slight change |

10 |

+ 1.00 |

Black, attacked |

|

|

50% |

30 |

- 0.06 |

No change |

10 |

- 1.14 |

Slight change |

|

|

Water, Synthetic Sea |

30 |

+ 0.13 |

No change |

10 |

+ 0.22 |

No change |

|

|

Organic |

Acetic Acid |

30 |

+ 0.87 |

Slight Brown |

8 |

+ 0.83 |

Slight brown |

|

Acetone |

30 |

+ 0.24 |

No change |

4 |

+ 0.45 |

No change |

|

|

Benzene |

30 |

+ 6.30 |

Slight change |

4 |

+ 8.11 |

Slight change |

|

|

Carbon Tetrachloride |

30 |

+ 18.8 |

Swelled, attacked |

4 |

+ 22.4 |

Swelled, attacked |

|

|

Ethanol |

30 |

+ 0.03 |

No change |

4 |

- 0.01 |

Slight change |

|

|

Ethyl Acetate |

30 |

+ 1.34 |

Slight change |

4 |

+ 1.86 |

Slight change |

|

|

Ethyl Ether |

30 |

+ 3.9 |

Slight change |

- |

- |

- |

|

|

Ethylene Dichloride |

30 |

+ 12.2 |

Swelled, attacked |

- |

- |

- |

|

|

Gasoline |

30 |

+ 4.81 |

Slight change |

4 |

+ 6.61 |

Slight change |

|

|

Oil, Licensed |

30 |

- 0.70 |

No change |

8 |

- 0.23 |

No change |

|

|

Olive |

30 |

- 0.50 |

No change |

8 |

- 0.12 |

No change |

|

|

Transformer |

30 |

+ 2.4 |

Slight change |

8 |

+ 6.35 |

Slight swelling |

|

|

Toluene |

30 |

+ 7.0 |

Slight swelling |

8 |

+ 10.9 |

Slight swelling |

|

|

Trichlorethylene |

30 |

+ 15.0 |

Swelling, brown |

8 |

+ 26.3 |

Swelled |

|

|

Xylene |

30 |

+ 7.1 |

Slight swelling |

8 |

+ 15.5 |

Swelled |

|