ULTROL is a registered trademark for UHMW-PE Idlers, which are manufactured and supplied by POLTEC Corporation since 1995. We have developed and marketed this specially designed idlers to the various users in material handling applications. The industry finally proved that ULTROL are extremely tough, durable, calm and economically acceptable. Carrier & Impact, Return and Guide rollers are available in market. Design features and advantages of ULTROL are not countable but we briefly describe the technical superiority as follows.

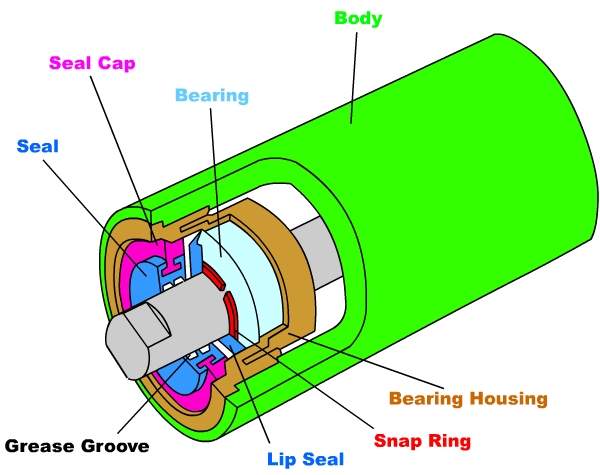

1. Cross-sectional View of ULTROL

2. Component materials

- Body : UHMW-PE

- Housing : Polymer with high impact strength and low thermal conductivity

- Seal : Rubber

- Seal Cap : Polymer with high impact strength

- Shaft : Carbon steel, S45C

- Bearing : KS Standard and equivalent to JIS

3. Seal Design Features

We take a special rubber design, which meets JIS B2402 requirement. A groove is made at the contact surface between shaft and seal to fill the groove with special grease. This design feature helps reduce the coefficient of friction.

4. Grease in use

We use an unique grease manufactured by Nye Lubricants, USA. This grease is a soft, non-melting, plastic & Elastomer compatible, salt-water resistant gel of the high viscosity synthetic hydrocarbon oil with temperature capability. This grease is mildly thixotropic: i.e. It becomes semi-fluid on agitation but returns to the gelled state when agitation ceases. In thin film the resulting lubricant is non-migrating. It can also protect vulnerable connector metals from oxidation and fretting corrosion, both of which can threaten connector reliability over long periods. Even though the grease itself is an insulator, and can be used as sealing compound. ( More detail specification of the grease can be provided upon request)

5. Bearing Housing Design

To increase the lifetime of bearing, we use a plastic having a high impact notch strength for the bearing housing. The housing is tightly joined with rubber for dust-proof.

6. ULTROL Advantages

- Due to self-lubricant features of UHMW-PE, ULTROL

allows material to fall off the belt, therefore keeping it clean. This

protects the expensive belt conveyor from wearing.

- Bearing housing and bearing cover are tightly sealed

and made by plastics and rubber. This results in sound dampness, impact

resistance and dust-proof. In fact, the lifetime of bearing and roller

can be extended.

- UHMW-PE plastics have a very low thermal conductivity.

Consequently, Grease in grease groove gets a little temperature variability

and seasonal viscosity changes.

- ULTROL is very suitable for abrasion applications

due to its low relative coefficient of abrasion. ULTROL is very durable

in harsh environment.

- ULTROL is light comparing with steel roller. This

design allows belt conveyor drive to require less electric power (this

will be addressed in a separate report.)

- Installation and maintenance of ULTROL is easy.

7. Comparison between ULTROLR and Steel Roller

|

Features |

Items |

Steel Roller |

ULTROL® |

|

Maintenance |

Weight |

≒ 14 kg/ea |

≒ 8.5 kg/ea |

|

Installation |

Heavy/difficult |

Easy |

|

|

Durability & Performance |

Surface Abrasion |

Bad |

Good |

|

Material Stickiness |

Adhesion |

Material falling off |

|

|

Water Pressure Test |

Not withstand |

Water, dust proof |

|

|

Corrosion |

Surface Corrosion |

Chemical resistant |

|

|

Lifetime |

12 ~18 months |

36 ~ 60 months |

|

|

Environment |

Noise Reduction |

Noisy operation |

Calm |

|

Recycling |

Yes |

Yes |

|

|

Price |

1 Set Price |

US$ 150 |

US$ 120 |